Blast chiller / Shock freezer

King Trolley

Thanks to the most advanced technology and user-friendliness, the blast chillers and freezers of the King Trolley range are intended to respond to the needs of small and medium industries, catering, cooking and preparation centers, canteens and workshops.

Extremely strong and resistant, these blast chillers are truly reliable in any working environment.

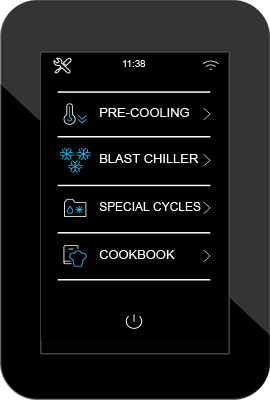

Control panel

- HACCP alarm log

- Quick blast chilling from +90°C to +3°C by time or by core probe

- Quick freezing from +90°C to -18°C by time or by core probe

- Automatic storage phase at the end of the cycle

- Choice between HARD and SOFT cycles in chilling and freezing mode

- RS485 serial port for connection to supervision systems

- Insertion of customized cycles

- WI-FI connection module for remote management (optional)

The King Trolley range

-

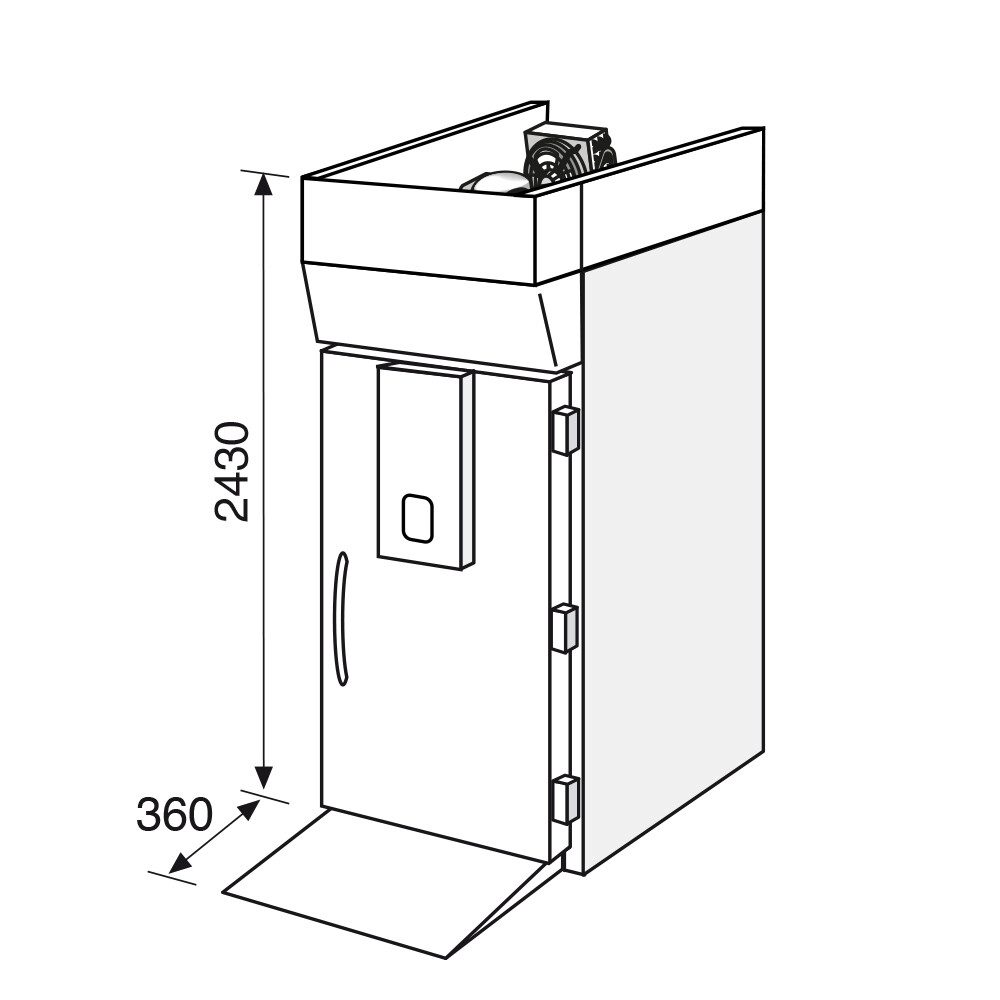

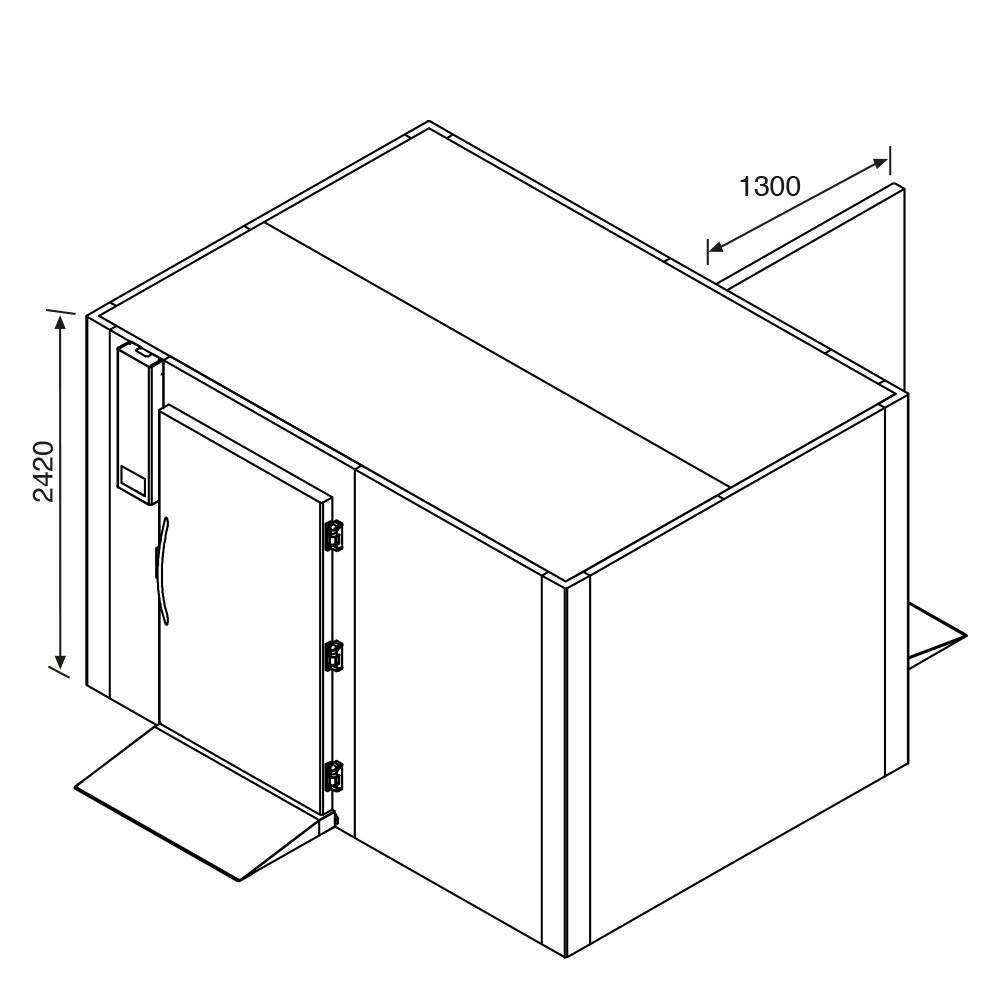

King Trolley 20 Compact

![gamma.png]()

-

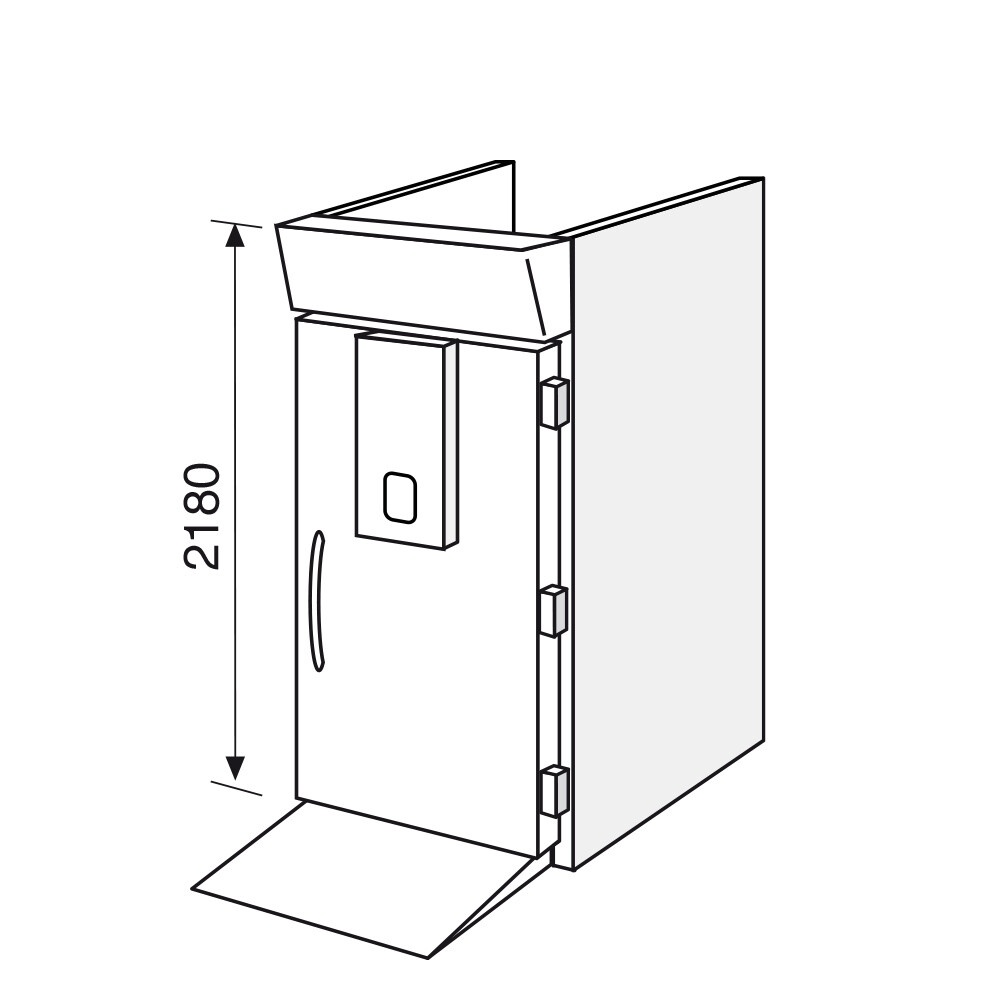

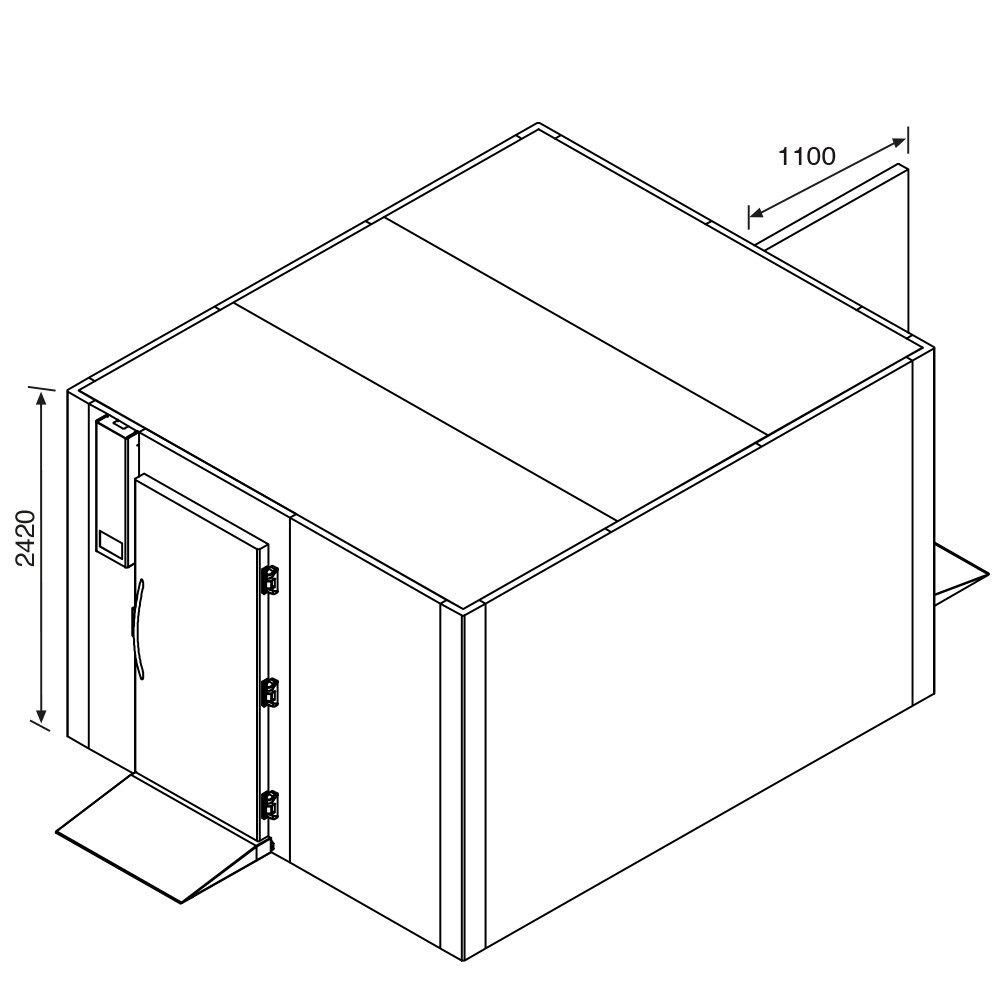

King Trolley 20 L / P

![gamma.png]()

-

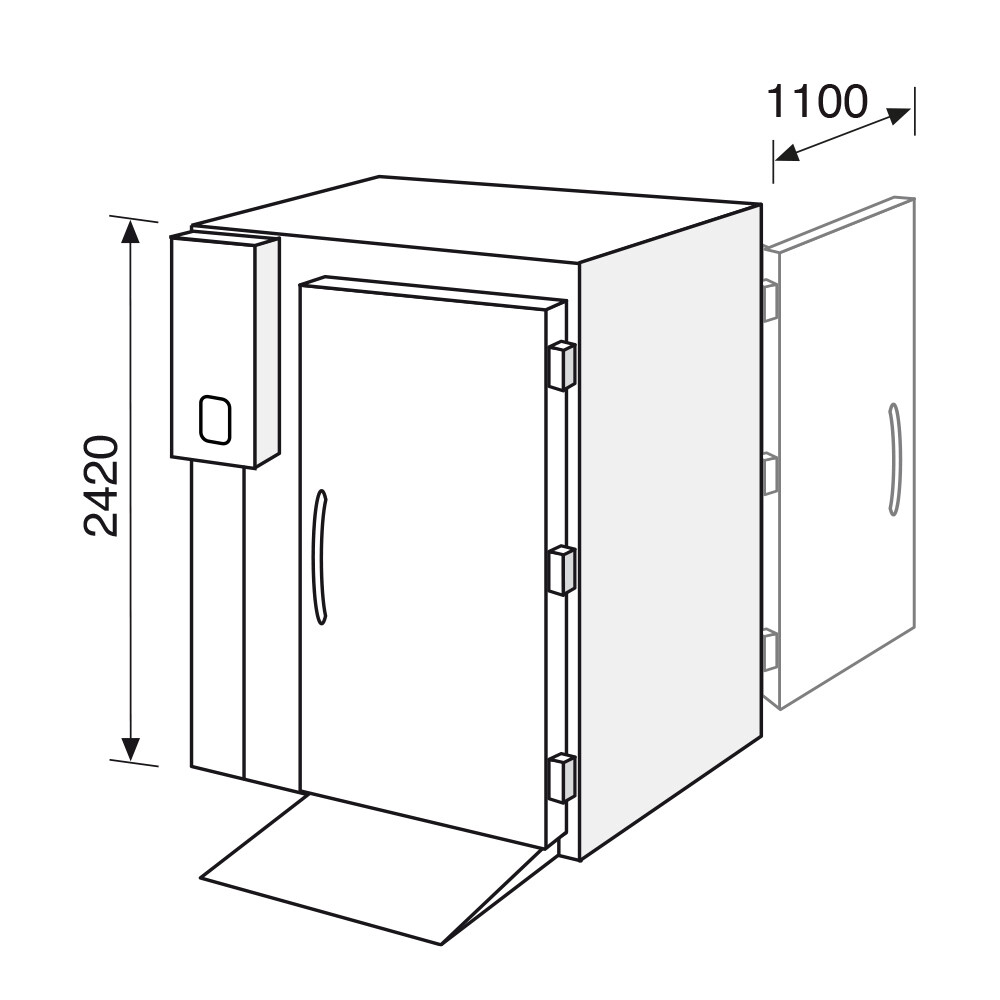

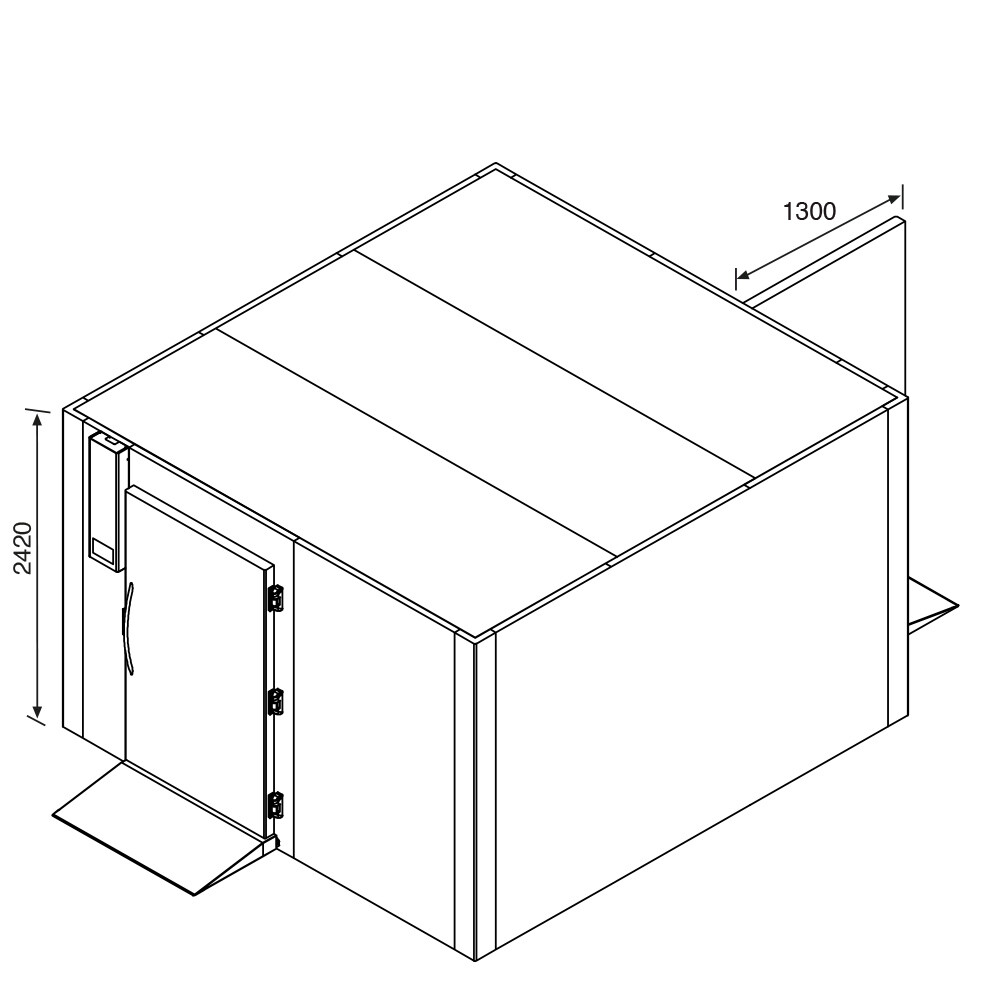

King Trolley 40.90 L / P

![gamma.png]()

-

King Trolley 40.110 L / P

![gamma.png]()

-

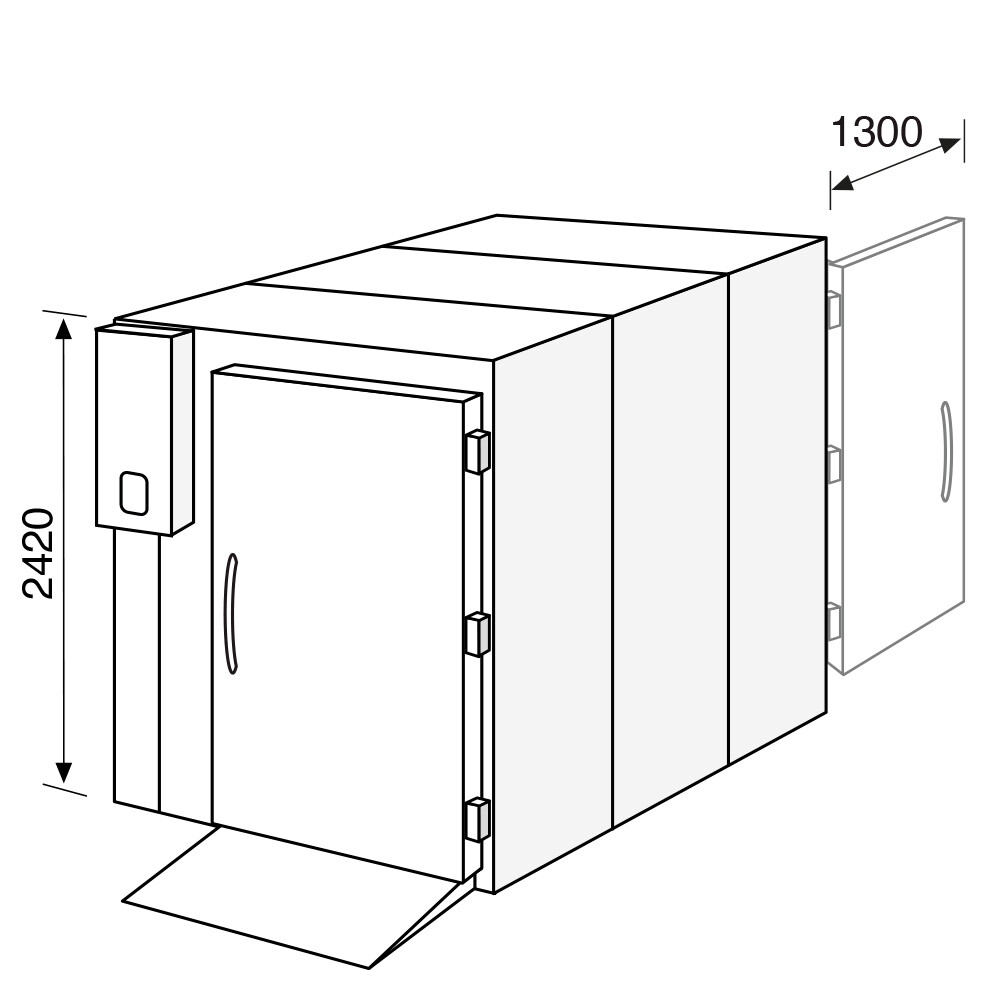

King Trolley 80.90 L / P

![gamma.png]()

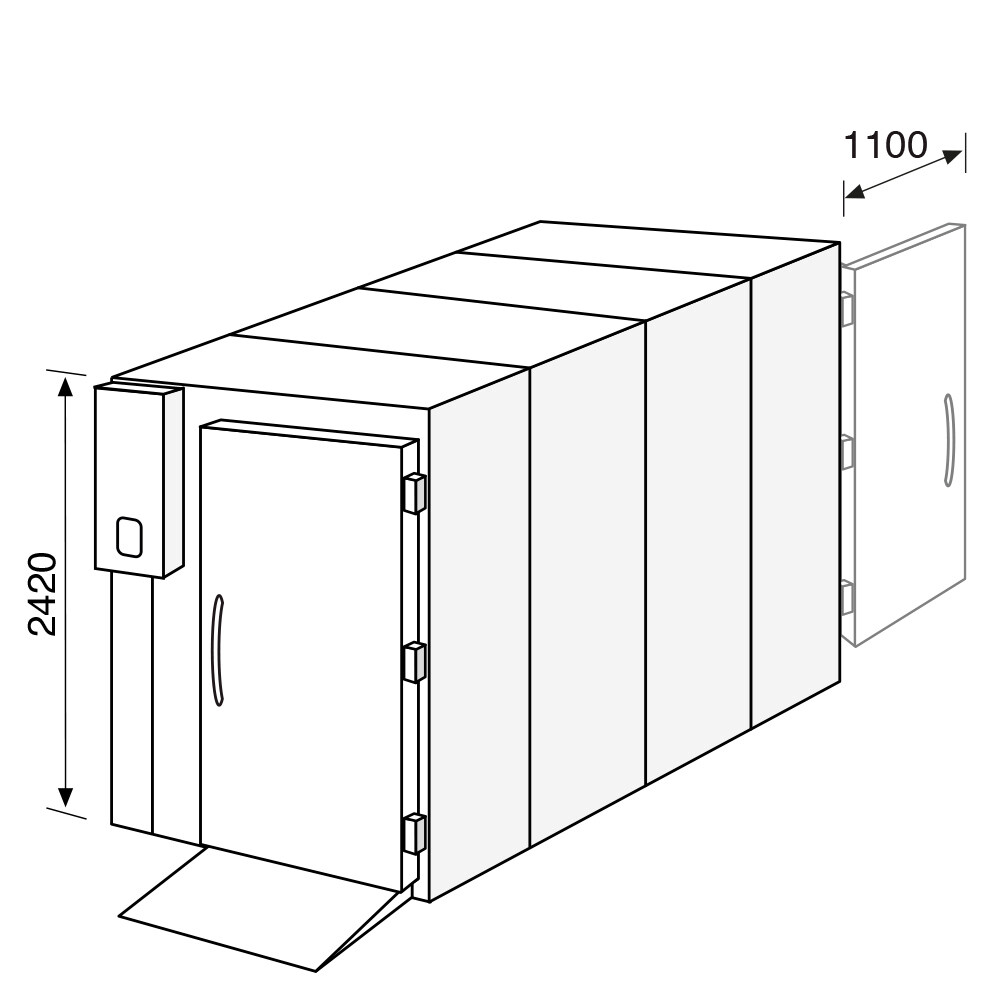

-

King Trolley 80.110 L / P

![gamma.png]()

-

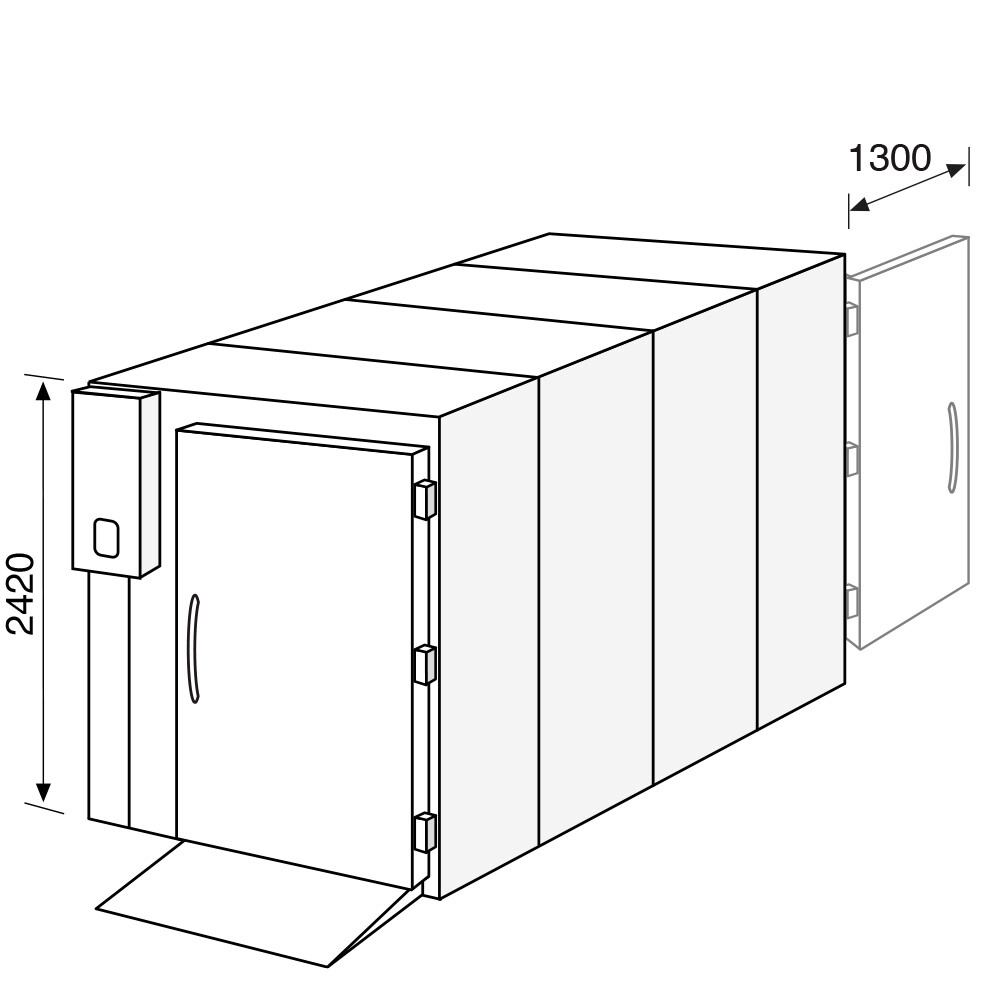

King Trolley 120.90 L / P

![gamma.png]()

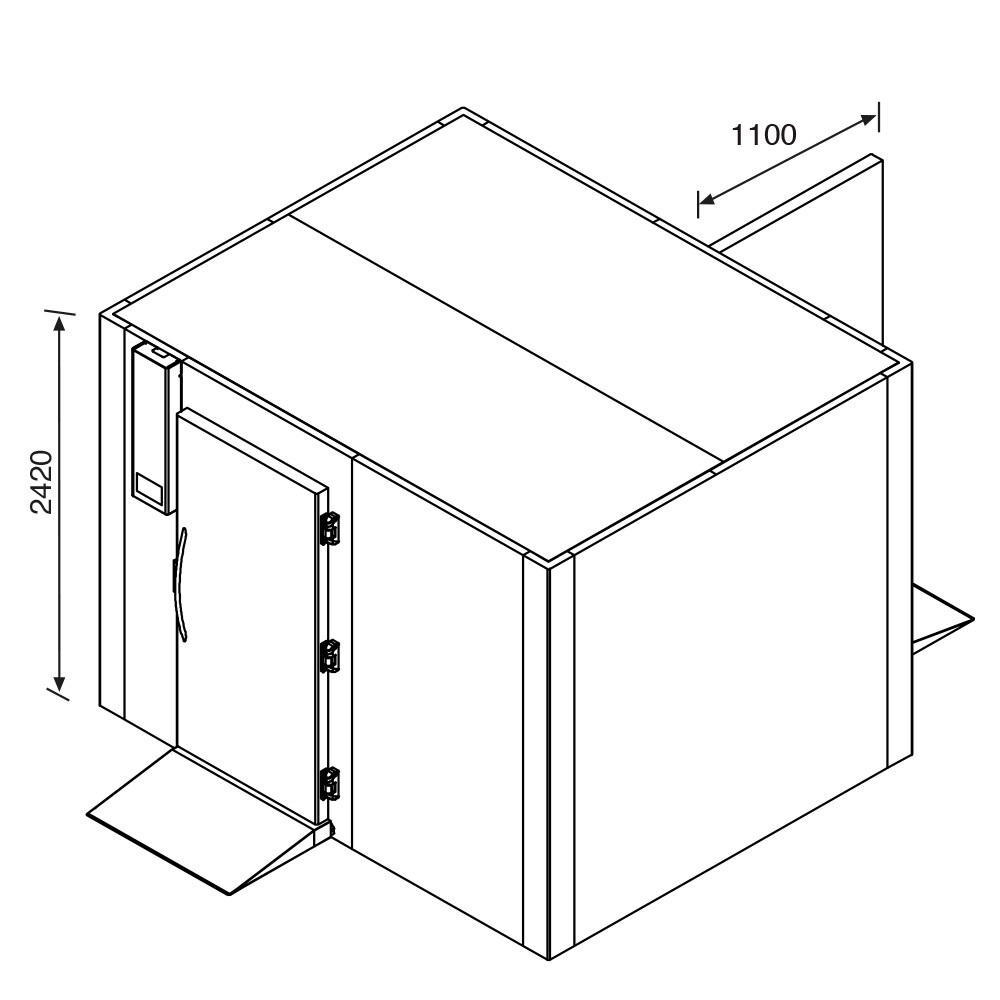

-

King Trolley 120.110 L / P

![gamma.png]()

-

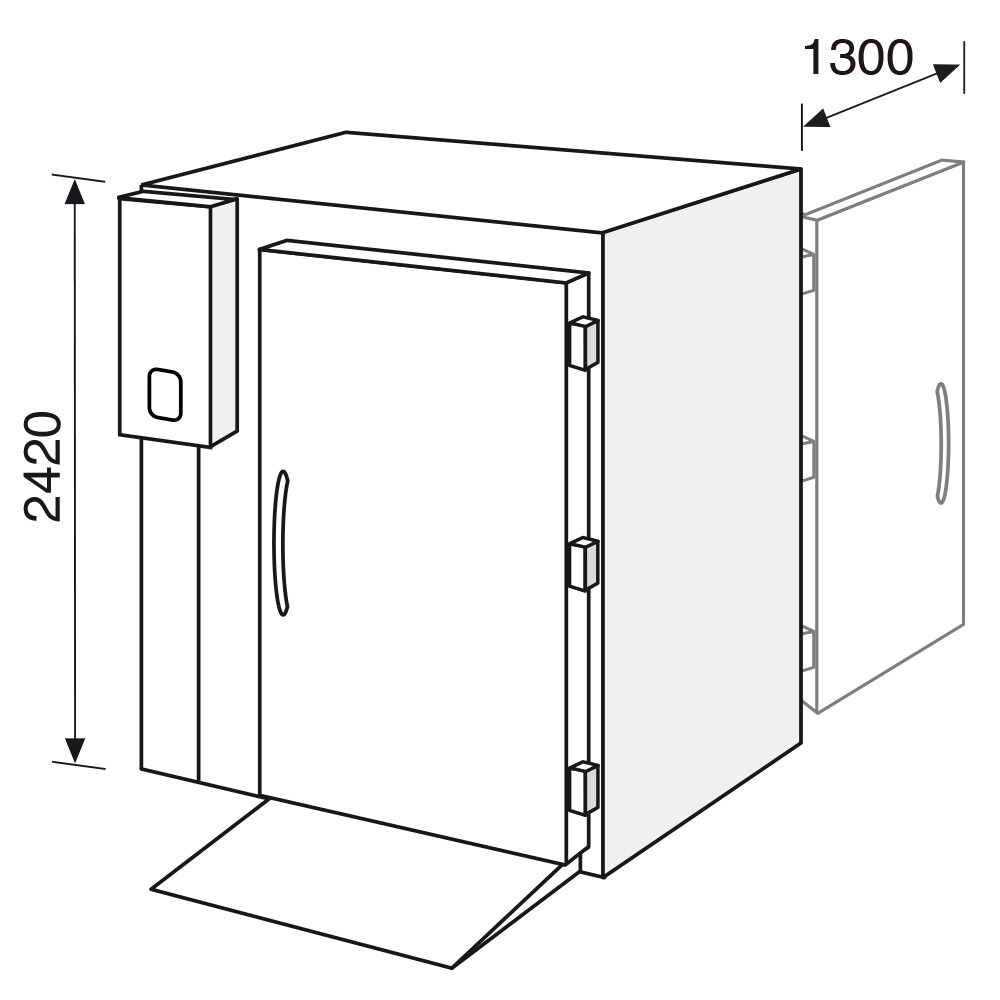

King Trolley 160A.90 L / P

![gamma.png]()

-

King Trolley 160A.110 L / P

![gamma.png]()

-

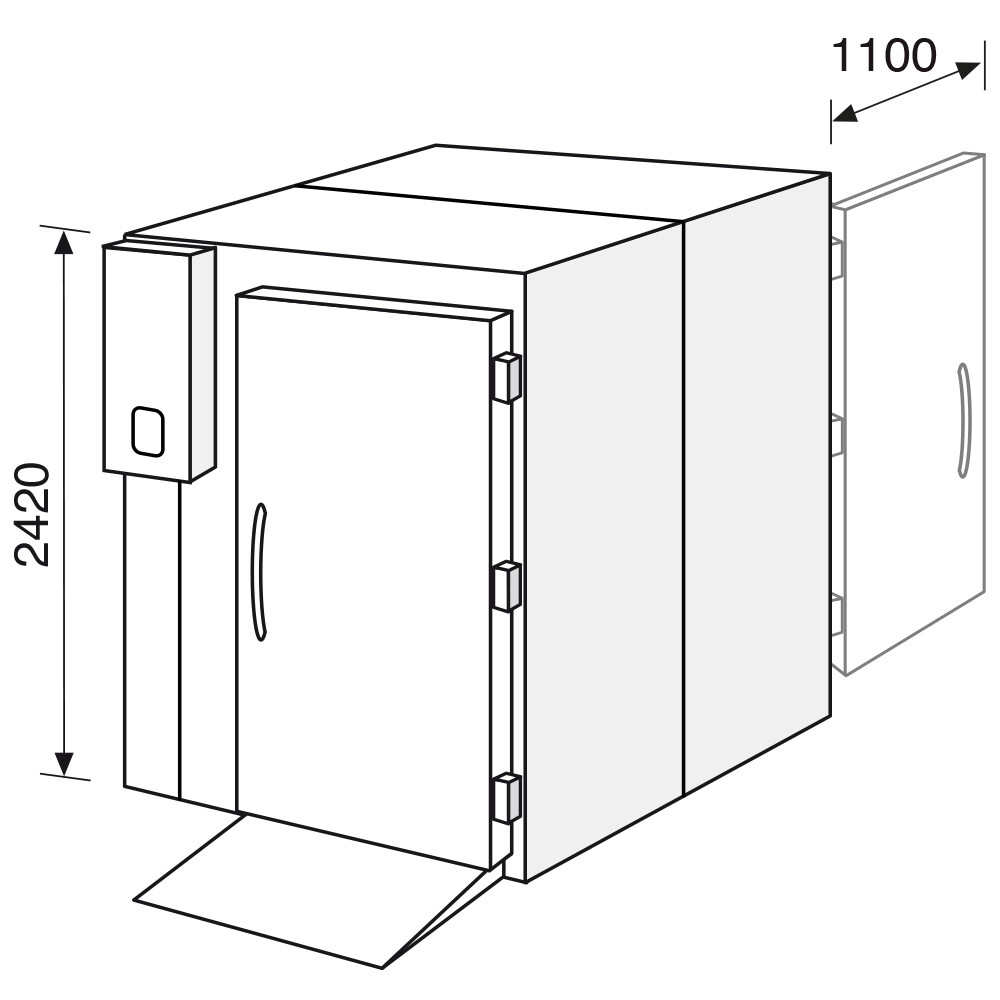

King Trolley 160B.90 L / P

![gamma.png]()

-

King Trolley 160B.110 L / P

![gamma.png]()

-

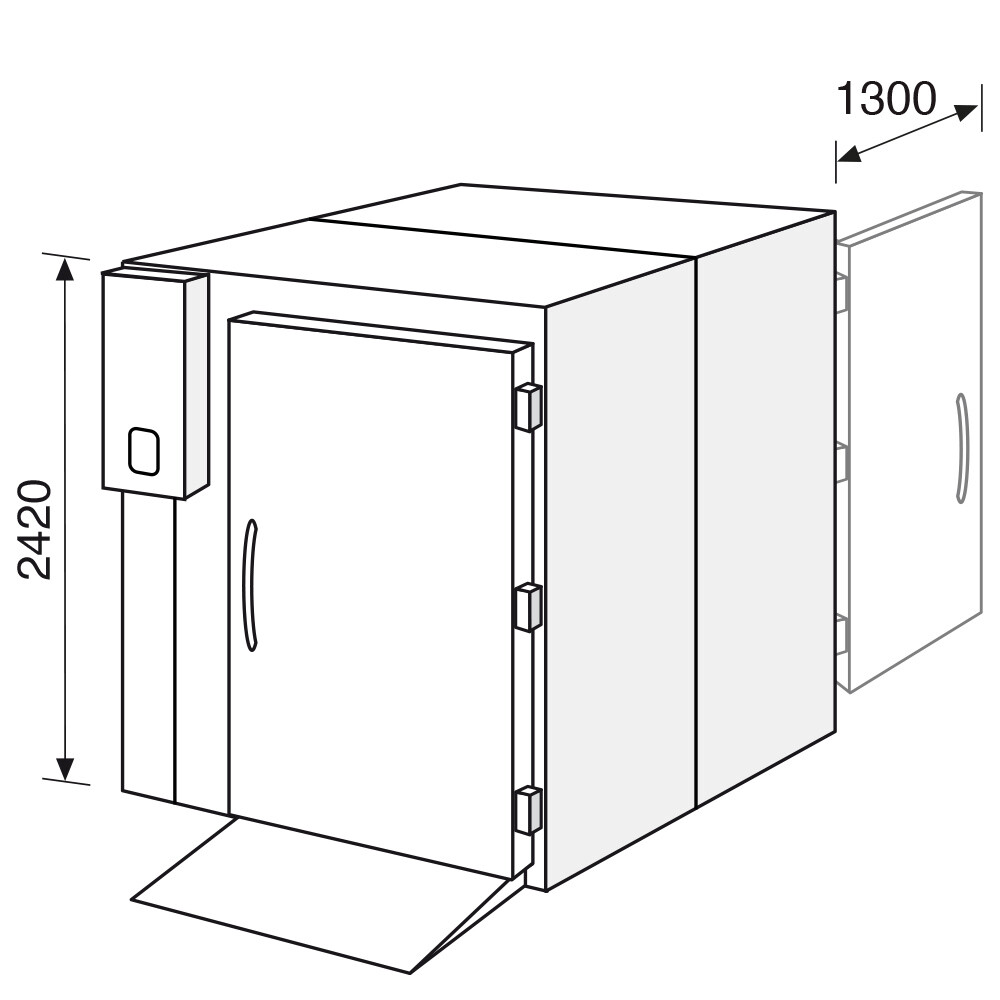

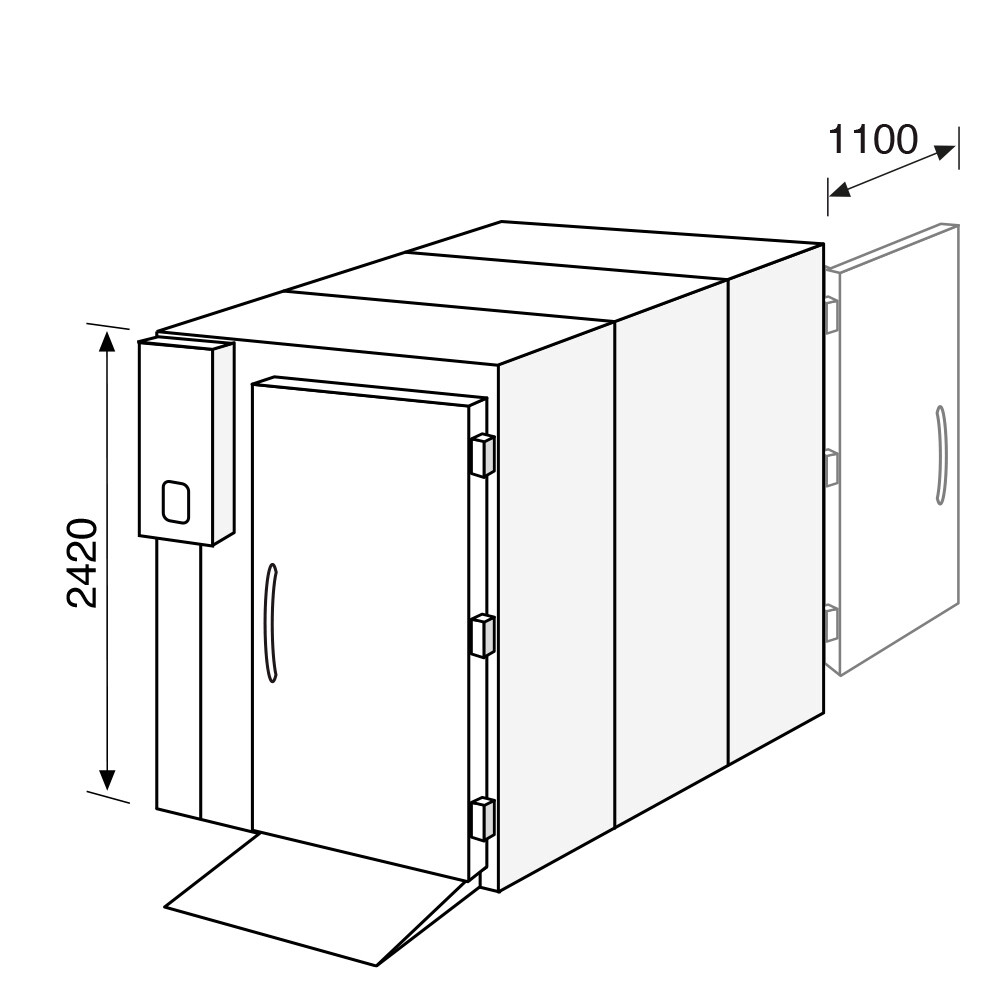

King Trolley 240.90 L / P

![gamma.png]()

-

King Trolley 240.110 L / P

![gamma.png]()