What is a blast chiller / shock freezer?

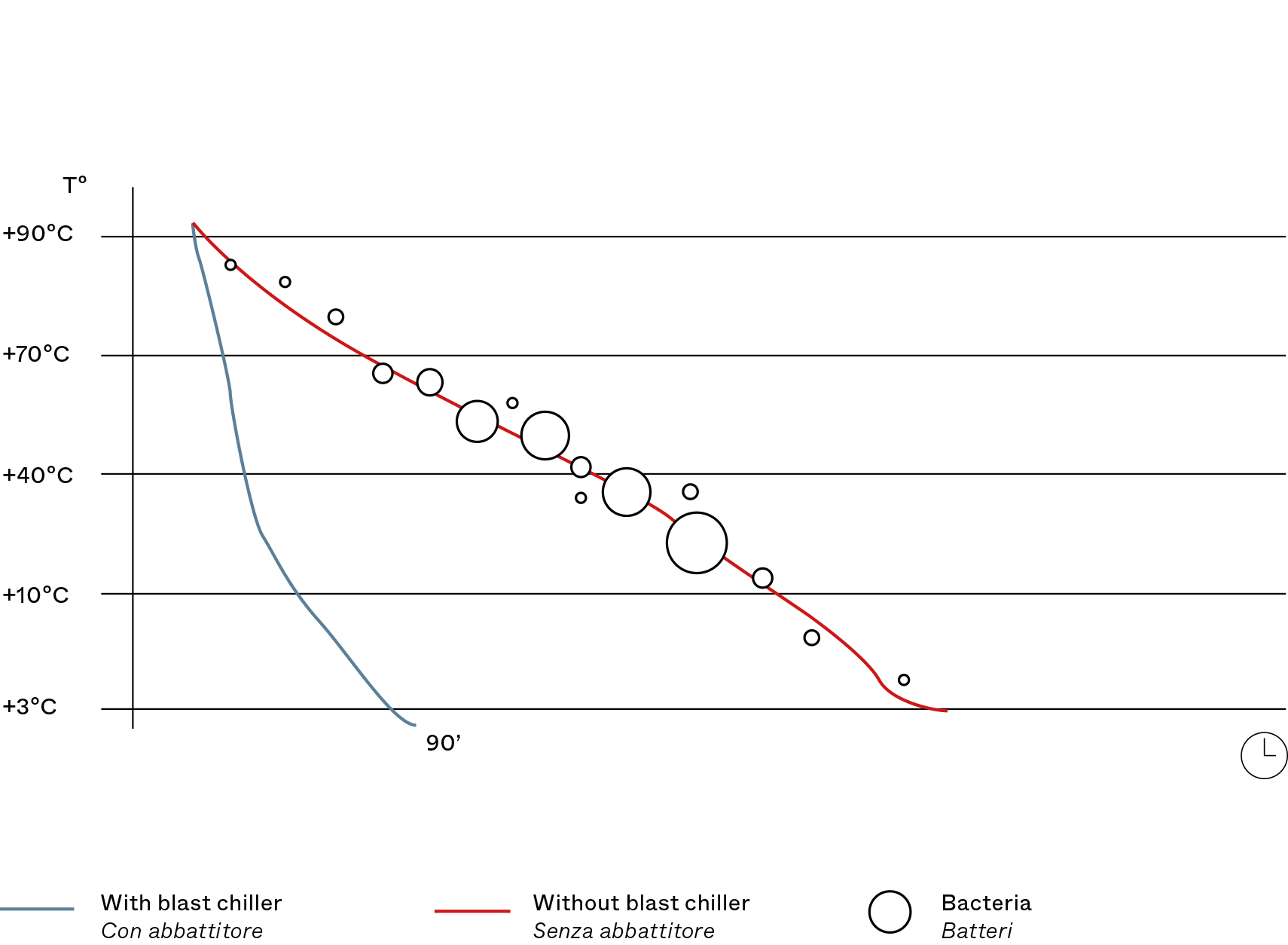

Blast chilling

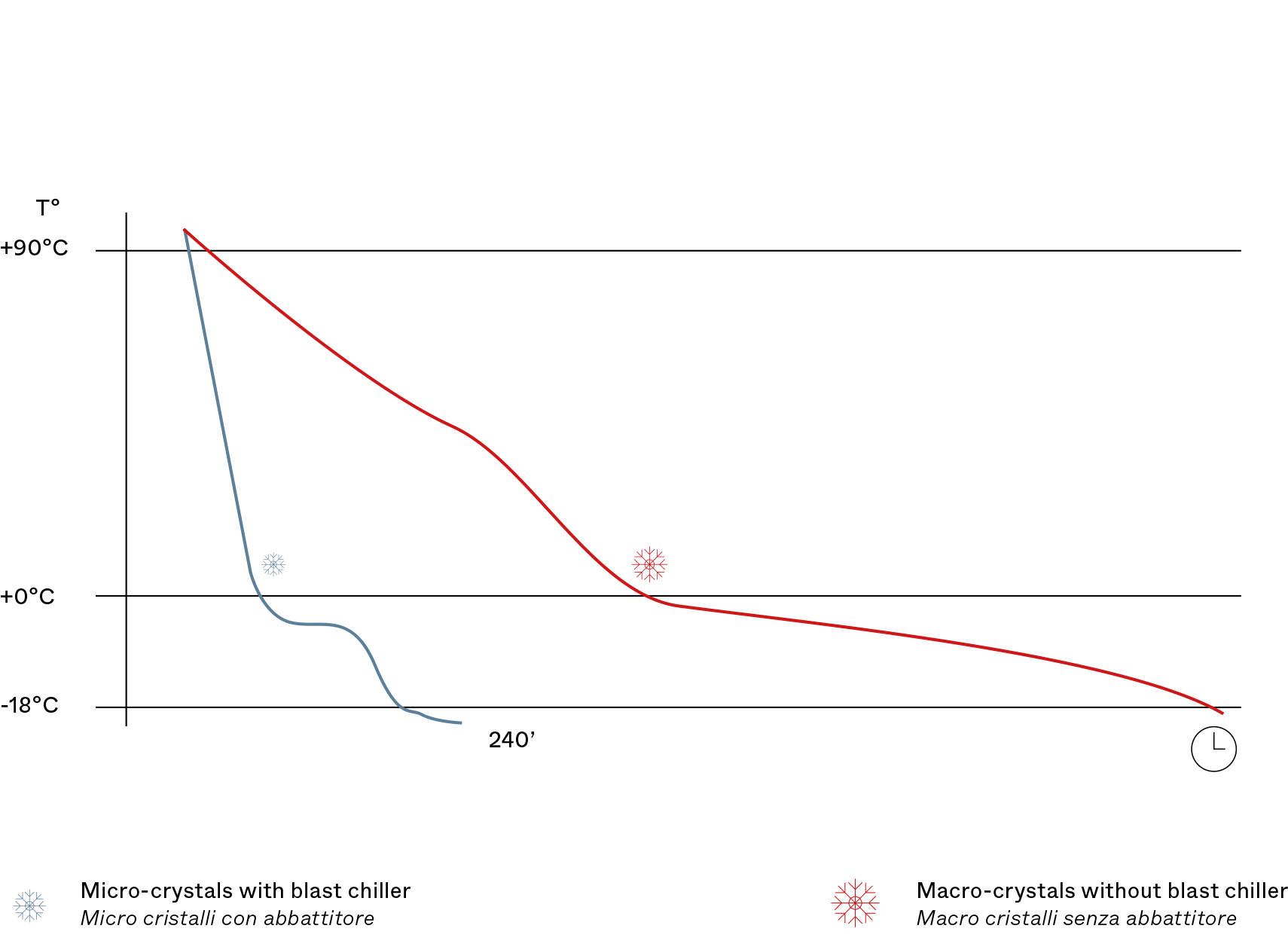

Shock freezing

SOFT FREEZING +90°C -18°C

Ideal for delicate, thin or small products that need to be frozen in order to be stored for many weeks or months, but in a gradual and not aggressive way. Air temperature inside the room never goes below 0°C until the temperature of 3°C is measured at product core during the first phase, and goes to -40°C during the second phase to complete the freezing process, reaching

the core temperature of -18°C.

HARD FREEZING +90°C -18°C

Ideal for dense, fat, big-size or packed products. The process reaches the required core temperature of -18°C as soon as possible. Air inside the room can go down until -40°C.

Models

Blast chillers Shock freezers for trays GN 1/1 / EN 60x40: Basic Tray

Blast chillers Shock freezers for trays GN 1/1 / EN 60x40: Professional Tray

Blast chillers Shock freezers for trolleys GN 1/1 / GN 2/1 / EN 60x40 / EN 60x80: King Trolley