What is retarding-proofing?

New "cold" systems for professional bakers

The use of cold in modern bakery technology arisen from new workign needs, whose main objective is to avoid night and holiday work.

Fermentation, i.e. the process stopping the leavening of dough, takes place inside specific appliances, designed for bakery and pastry dough, by correctly managing temperature, humidity and time. Retarding-proofing takes place in retarder-proofer cabinets, where dough is stored in an insulated and controlled enviroment, so as to allows products to autonomously leaven according to the time schedules set by specific programs.

The retarding-proofing process

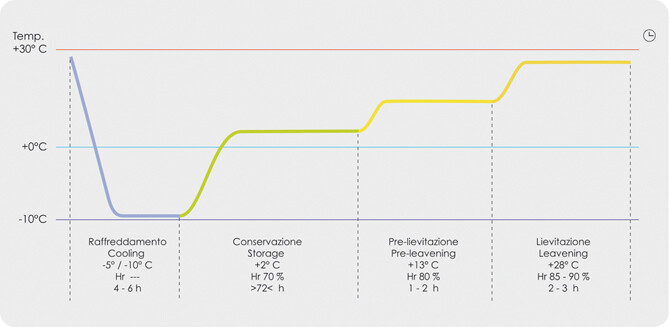

The complete retarding-proofing cycle through specific cabinets is divided in 5 phases:

- Chilling: dough is chilled between -5° and -10°C for a period from 4 to 6 hours;

- Storage: the second phase stores dough at a temperature of 2°C and constant humidity;

- Awakening: pre-leavening takes around 1-2 hours;

- Leavening;

- Delayed baking or wait

It is worthwhile to remember that specific internal conditions can be set for the leavening phase, according to the type of product.

Everlasing's Retarding-proofing Cabinets and Tables stop or slow down yeast activity, keep dough in this state up to maximum 72 hours and automatically start fermentation at the time set by the program.

The advantages of retarding-proofing

- Elimination of night work. Bakers knead and prepare the various types of raw bread during the day, then store them into retarding-proofing appliances and, by simple programming, automatically delay leavening in the early morning, so that bread is already ready to be baked upon their arrival.

- Improvement of product quality: long leavening gives bread more flavour and extends its duration.

- More profits, thanks to the rationalization of production processes, entailing less yeast consumption and consequently no unsold bread at the end of the day.

- More quality for your products.

Baking flaws and useful tips for the use of retarding-proofing appliances

The most common baking flaws

The most common baking flaws are:

- Too soft dogh;

- Too cold dough;

- Too hot dough;

- Low-quality flour;

- Too much humidity into the appliance;

- Too hot oven;

- Too much steam.

Useful tips to use Retarding-proofing appliances

How to use retarding-proofing?

- Cool the chamber before inserting products (-5°):

- Insert products in the chamber shortly after dividing them;

- If improving agents are used, it is necessary to use those suitable to cold;

- Use high-quality flours;

- Do not exceed with yeast;

- If possible, do not bake products just out of the retarder-proofer; it is advisable to let them dry to avoid crust defects.

Do not hesitate to contact us for information regarding our professional retarding-proofing cabinets.